Fuel Efficiency

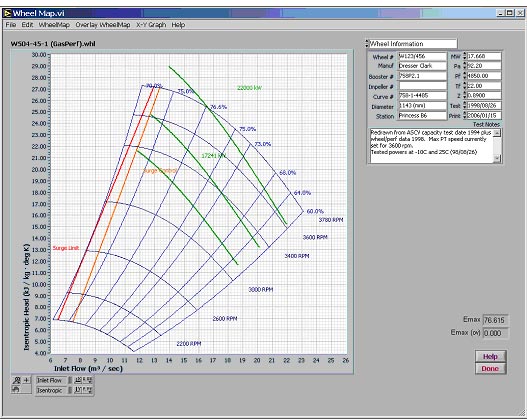

By knowing the actual characteristics of compression units, rather than just the manufacturer's claims, you can predict exactly where the units will operate at given flow conditions.

By incorporating "as installed" wheel maps into a model of the pipeline, your Gas Controllers can choose to operate the combinations of units which will give the highest fuel efficiency. This can increase overall fuel gas efficiency by several percentage points: a significant reduction in operating costs for most pipelines.

Fuel costs

In a typical natural gas pipeline, the percentage of gas transported which is used as fuel gas is around 2%. Improving the efficiency by a few percentages points translates into millions of dollars on a significant pipeline.